-

George Gruhn

Martin Bodies in the 19th Century

Size matters

Exactly when did C.F. Martin begin formally using the two-part system indicating size and level of ornamentation on his instruments? Nobody knows for certain. Martin was thinking along these lines by 1848, when he received an order for “1 large Degoni (sic), ivory edges and double side screws, ff (very fine) case $26.00” – clearly…

-

George Gruhn

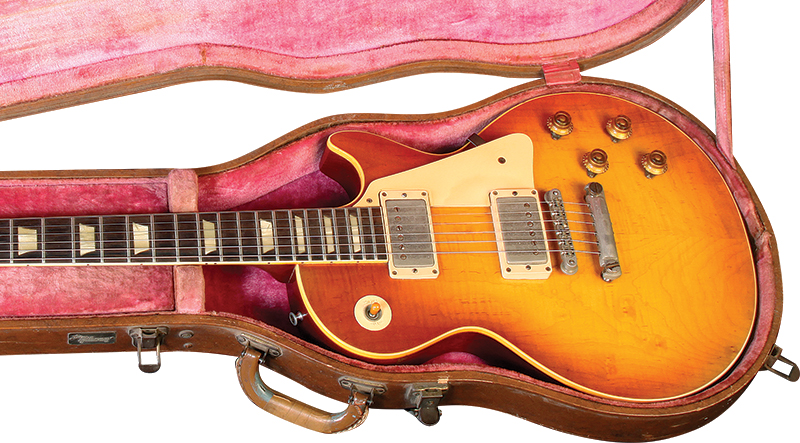

The Cost of Protection

100 Years of Instrument Cases

Modern guitars are typically sold with a hard case. But that wasn’t always so. Here, we look at the history of the relationship between cases, guitars, and those who’ve bought them.

-

George Gruhn

One of Two of a Kind

Gibson’s L-3 Ganus Brothers Special

Making custom instruments has always been problematic for companies designed to manufacture in quantity. Though it had an unenforced policy against one-off projects, this guitar illustrates how the company did just that and demonstrates the struggle between accounting and public relations.

-

George Gruhn

’53 Gibson Les Paul Junior

Gibson records say the Les Paul Junior was introduced in 1954. But this instrument has tone and volume pot codes from ’53. It also differs in regard to other specifications, most notably that its neck joint is unlike that on any other Junior.

-

George Gruhn

Martin D-28 and D-45

Definitive Flat-tops

Martin’s pre-WWII dreadnought guitars set the standard for the modern flat-top, and thus both have been inducted into the VG Hall of Fame.

-

George Gruhn

D’Angelico New Yorker

Top of the Line from a Master Builder

Having earned its place in the VG Hall of Fame as one of the finest guitars in the history of the instrument, the New Yorker is significant primarily due to its superb quality and aesthetic artistic appeal, rather than being an innovative instrument.

-

George Gruhn

Guild F-512

Iconic ’70s 12-String

Today, players typically equate the 12-string acoustic with Taylor and Martin. For its part, though, Guild’s F-512 remains one of the most revered, and this particular one veers off-spec with its one-piece mahogany neck, stacked heel, and other unique features.

-

George Gruhn

Silver Lining

Gibson and the Master Models

Recognized today as visionary, when introduced in 1922, Gibson’s Master Model L-5 and F-5 were expensive to produce and lacked a market. For a time, they placed a considerable burden on the company.

-

George Gruhn

Stromberg Master 400

Considered by many to be the ultimate orchestral rhythm guitar, these very rare instruments are among the most sought-after, and possess a sound epitomized by a power and projection unsurpassed by any other archtop acoustic.

-

George Gruhn

Border Crossing

C.F. Martin and the Influence of German and Spanish Guitar Designs

It has often been said that today’s Martin guitars are direct descendants of the instruments made in Vienna by Johan Georg Stauffer, whose apprentices included one C.F. Martin, Sr. It is indeed true that about 25 percent of the earliest Martins labeled with the New York address (made after he moved from Germany in 1833)…