1863 Antonio de Torres

Antonio de Torres was the most important guitar maker of the 19th century, exerting an influence worldwide on the design and construction of the modern guitar that is unrivaled in the history of the instrument. His model has been in continuous usage since its creation in the mid 19th century and today is the de facto model of nylon string players the world over. Of the 300 to 400 or so guitars Antonio de Torres was thought to have made in his lifetime, about 90 are known to survive, so when a previously unknown example comes to light, this is of considerable importance and interest to scholars, collectors, and musicians alike.

Surprise Arrival

In 2004 I received for restoration a highly interesting and previously undocumented Antonio de Torres of 1863 which had been in the same family for several generations. Unfortunately, due to neglect, it was in very poor (unplayable) condition, although it retained its original varnish despite amateurish repair attempts. At some point, possibly in the early 20th century, someone crudely converted the instrument from its original friction pegs to mechanical tuning machines, installing a poor-quality set of machine heads. Internally, the numerous cracks that had occurred had been “repaired” by slathering copious amounts of hide glue around and pressing pieces of paper, cloth, scrap wood and such in a misguided attempt to consolidate the cracks.

The sides of the instrument, which average only .8 mm thick(!) had suffered particularly, as it appeared the instrument had been exposed to wet conditions which allowed the guitar to repeatedly swell and shrink. Given the thinness of the sides, they reacted very quickly and the result was more cracks than could be counted that required attention. The restoration would require removal of the back – major surgery for a guitar.

The back had been previously removed (perhaps on several occasions) and replaced, and shrinkage had caused several bad splits in the mahogany center pane. These cracks were crudely inlaid with non-matching pieces of cypress. A small corner of the back panel was missing altogether, replaced by a hunk of foreign matter. Because the shrinkage of the back precluded closing the cracks and reinstalling the back, after consulting with Mr. Takeshi Nogawa, who works in the restoration shop of Chicago violin dealers Bein and Fushi, we formulated a plan to remove the badly done inlays, close the cracks, add matching ears to the center panel edges to expand the dimension and then double the interior using a matching piece of the same species of mahogany. Doubling is often done on rare violins where soundpost cracks and bridge distortion have created otherwise insurmountable problems. This procedure allowed the crack on the pearwood back panel to be closed completely (rather than inlaid) and for the back to be perfectly reinstalled to the original outline, something that would have been otherwise impossible due to shrinkage. The doubling was done in such a manner to make it invisible from the outside, using a matching piece of mahogany, right down to having a knot in the same position as the knot in the original Torres back panel. All agreed this was preferable to replacing the center back panel with a completely new piece, and allowed the instrument to retain all its original components.

The top showed many cracks, all due to shrinkage. A section on the bass side which had gone missing had been crudely replaced with a piece of unmatched spruce. By carefully closing the cracks, installing a matching panel and re-inlaying some of the larger cracks previously inlaid with better matching wood, the top was brought back to its original outline and re-purfled perfectly, with no loss of original varnish. The Cuban mahogany bridge was worn, but otherwise perfect, retaining the arching that held the top dome, and the worn string holes were carefully filled in to restore the wear of nearly a century of mounting strings. The bridge is a very critical element to the originality of the instrument, second only to the soundboard and varnish, so it was vital to retain the bridge without alteration.

Singularly Unique

The most remarkable feature of this Torres is without question the absence of fan strutting on the top, the only Torres known to have been made in this manner, according to José Romanillos (whom I consulted regarding this guitar). This certainly suggests that Torres did not view fan strutting as a structural element, but rather as a sound-controlling element. The small size of the instrument means that compared to larger bodied guitars, it would not have as much bass response. Adding fans to the top raises the upper frequency response, as does making the fans stiffer, so making the guitar entirely without fans suggests Torres correctly believed this would benefit the lower bass range of the instrument, and indeed, it has surprising depth to the sound, much greater than one would expect for such a small body.

The top after restoration. The original varnish remains intact over the entire instrument. The top averages about 2 mm thick.

The back after restoration. Torres used bookmatched pearwood with a central panel of mahogany. The sides are pearwood, and are only .8 mm thick. The back averages around 2.5 mm thick. There’s only one cross strut on the back, by the lower bout.

Interior after removal of the papers and crack inlays. Note the absence of evidence of fan strutting. The braces on the top are the only ones installed by Torres. Note the glistening surface of the top, left as it was cut with a very sharp plane, without sanding or scraping.

The head with the new Rodgers tuning machines. Note the inside face of the slots, by the second string roller; the faint mark remains as evidence of the original friction pegs.

The fingerboard retained the original graduated-brass-bar frets Torres sometimes used during this period of his work, something of a miracle given the amount of hard playing the instrument had seen during its life. But the fingerboard was badly split due to shrinkage, and the frets and fingerboard surface were severely eroded. So after consulting with the owner, it was decided the best solution was to remove the original fingerboard with the frets intact, and replace it with a copy of the original, which is now preserved with the instrument. This proved a real problem, as identifying the species of wood used for the fingerboard was not easy. After consulting with Robert Ruck and Neil Ostberg, both eminent luthiers with vast experience in these matters, we concluded that the original fingerboard was made of Circassian walnut, a material Torres would have had access to. So it was replaced with the same material using graduated-bar fret stock, as Torres had used originally. The action was preserved as Torres had originally set it, which by today’s standards is fairly low, but typical for 19th century Spanish instruments.

The head is interesting in that its design is different from the classic Torres triple-arch model typically associated with his guitars (a design derived from tombstones of the 19th century). It’s quite similar to that used by Manuel Gutierrez, of Sevilla, with whom Torres shared shop space on the Calle de la Cerregeria when he first moved to Sevilla. A second Torres from 1857 is also recorded by Romanillos with the same head design, this one owned by Yale University (No. 4574). Unlike this 1863 guitar, the 1857 retains its original pegs, although the head has plugged holes which suggest it may have been recycled from an even older guitar, perhaps one made for six courses rather than six single strings. This 1863 instrument has the neck and head made of a very lightweight pine rather than Spanish cedar, and the back of the head has had a wedge added to augment the thickness of the head when it was converted to mechanical tuning. From the front you can see the two smaller holes at the top of the head which were intended for a ribbon to allow hanging the guitar from a peg on the wall, the normal method of storage in 19th-century Spain. The added wedge, which is made of the same kind of pine does not have the holes drilled through it, as the new slots in the head would suffice for the hanging ribbon. The original Torres head tapered considerably in thickness, being much thinner out by the tip than it is by the neck, a normal Torres feature for instruments with friction pegs. A custom set of machine heads by David Rodgers was made to exactly fit the original machines, which were spaced at 35.5 mm.

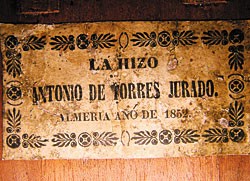

Original Label

The label is the earliest printed label used by Torres, and the only one he printed that gives his location as Almería, his home town. It is also the only label he had printed with all four digits of the date printed in place: 1852. Romanillos, in his book on Torres, speculates about the many interesting possibilities this suggests, and recently indicated to me that he had seen an authentic Torres guitar with this label that had not had the date altered, presumably made in 1852. All of the other Torres guitars (including several in my own collection) which have this label have had the last two digits altered, usually to either 1863 or 1864, which suggest he ran short of his other labels and, having these leftover (due to the dates being wrong), he used this label as a practical expedient by overwriting the last two digits. In this instrument he wrote “63” over the “52.” This suggests the instruments bearing this overwritten label were mostly made between late 1863 and early 1864. There are known Torres instruments of both 1863 and ’64 with his normal label installed, so my best guess is he ran out of his regular labels temporarily and while the printer was making new ones, used these as an expedient. The only curious fact in all of this is that the family who owns this instrument is from Almería, and it seems the instrument has been in their possession since Torres’ days. Unfortunately, there are no sales receipts, etc., so perhaps it was purchased in Sevilla by a fellow Almerense and brought back to Almería where it remained the rest of its life.

Notable Features

Aside from the lack of fan struts, there are several other notable features. The first is its adherence to English measurements based on the inch. The 632 mm scale is actually a 25″ scale, with the 12th fret falling at precisely 1215/32″, which allows the bridge to be placed with compensation for a 25″ scale. The other dimensions of the body were also measured in inches rather than metric; for instance, the sides at the butt are 33/4″ deep exactly, the body is 163/4″ long, etc. The second is the strong presence of very fine and regular toothing blade marks in the interior work of the instrument. The blade that produced these was not a locally made blade cut by hand, but a very precise highly technical iron of precise spacing intervals. These are the same tool marks I’ve observed in other authentic Torres guitars. Together, these facts suggest Torres was using very high quality tools, probably of English manufacture, not surprising given the precision of his work, but not something one would have thought a simple carpenter from Almeria would have had easy access to in 19th-century Spain. Perhaps this was one of the benefits of moving to Sevilla, which was a major commercial center not only for wood and tools, but also for the marketing of flamenco music, which is where most of his clientele earned its money.

This was the only Torres label that lists his hometown of Almeria, and gives his mother’s last name (Jurado). “Me Hizo” indicates who made the instrument, and as a practice was going out of favor with Spanish makers at the time. The last digits have been overwritten with “63,” the year this was made, when Torres was working in Sevilla (not Almeria).

The linings, carefully crimped to permit bending without a hot bending iron. Note the perfect scarf joint where the center lining meets the upper lining. On the sides are the very fine tool marks left by Torres’ toothing plane (the side cleats were added during restoration). This type of lining was easy to do, but Torres’ execution is masterful beyond requirements of the design, and proves his work has not been surpassed.

Tip of the head showing the wedge added to allow for machine heads.

Also very notable is the design of the bridge, which harks back to the days of the lute and baroque guitars. It does not have the additional bone saddle in front to define the vibrating end of the strings, but instead has a simple forward-sitting tie block which allows string vibrations to be stopped by the loop of the string where it ties on the bridge. The string itself is its own saddle. This gives a different texture to the sound, something more akin to the tonal quality of the lute. Contrary to expectations, the sustain of the instrument is still very good, especially considering the fingerboard is made of walnut, which is much less dense than rosewood or ebony. Several other Torres guitars have been identified with this style of primitive bridge, most notably the very famous “La Leona” of 1856 which was played for many years by Julian Arcas, the 19th-century performer most instrumental in collaborating with Torres when he created his model. The advantage of this type of bridge is that it can be much lighter in weight, having a much smaller footprint on the top. The heavier the bridge, the more the muting effect on the sound. Torres selected Cuban mahogany to make the bridge, a wood that is light and very dimensionally stable, and the bridge still retains the original doming where it was glued to the top.

Working Methods

The interior linings are made of very lightweight softwood, and were crimped with a unique tool to assist in bending them to the outline. Romanillos refers to this technique as “green stick fracture,” and indeed some of the cheap Valencian hack attack guitars used this technique of forcing freshly cut wood around the outline by partially breaking it as you go, but in the case of Torres, this was not his technique at all. He used a very sharp knife edged mandrel, perhaps in a kind of arbor press to very uniformly produce cut kerfs in the very thin (3/32″) linings, allowing them to bend around the very thin and fragile sides without distorting the sides from the intended outline. The linings are installed in three sections around each side, a waist section with the crimps facing the glued side, and an upper and lower section with the crimps facing the interior of the body, with perfect scarf joints where the sections meet.

After the sides were bent, lined and slipped into the neck slots, he placed the tapered top cross struts across the assembly, and holding them in place used his saw to mark and cut their positions in the linings. The saw slightly scored into the already delicate sides as he cut through the linings, but this is how Torres fitted each cross strut so that there was absolutely no gap between the end of the brace and the linings. The triangular glue blocks on the ends of the cross struts fit so tightly they’re almost superfluous, and the tapered cross section means they cannot drop lower. The cross struts were first glued in place and then the top was glued to the side/neck assembly. This is the reason the two reinforcement pieces by the soundhole fall far short of touching either cross-strut. It is also possibly the reason the cross struts are slightly tilted off of 90 degrees to the center line of the top, as Torres probably did this by eye. On the other hand, they are tilted toward the treble, and one wonders if this was intentional, as later makers such as Santos and Barbero intentionally tilted cross struts, as do many modern luthiers.

The top is made of three pieces of unmatched very-fine-grain spruce, with the joint lines falling exactly under the placement of the soundhole reinforcing plates. The interior of the top was left perfectly smooth from a very sharp hand plane, without further sanding or scraping, as were the cross struts where they were rounded over with a small finger plane. The only part of the top that shows tool marks is the area by the interior waist on the bass side where there was a knot in the wood. In this area, only Torres judiciously used the same toothing scraper to deal with the wild grain around the knot. Every luthier who has seen this interior top surface has marveled at the sharpness level Torres must have maintained on his tools to permit this kind of surface treatment. This indicates his sharpening system was highly sophisticated, equal to anything in use today. And his tools themselves must have been made of very high-quality steel, capable of taking and holding such an edge.

Conclusion

It would be easy to dismiss this instrument as a simple “player’s guitar” and indeed, it was probably intended for a player of modest means, but in making this guitar, Torres used every ounce of his sophisticated methods and technology that he used in his most ornate instruments to produce an instrument that, while small and simple in appearance, was heads and tails above the work of his contemporaries in terms of musicality and playability. What a revelation it must have been to pick up this small guitar and hear it fill the room, to experience the huge depth of sound, the brilliance of its carrying power, and the ease of action that made it all so effortless. Players must have been convinced Torres had made a pact with the devil to achieve these kinds of results with such simple materials. Indeed, the devil is in the details.

Acknowledgments

I wish to thank several people who have kindly provided consultation, encouragement, and advice during the long period of restoration this instrument has undergone: Luthiers Robert Ruck (Oregon), Neil Ostberg (Wisconsin), Takeshi Nogawa (Chicago), and my son Marshall Bruné (Salt Lake City). Their sage advice was invaluable. Special thanks to Robert Ruck, who identified the material of the original fingerboard, and provided an aged sample to use for the replacement. My thanks to luthiers James Frieson (Japan) and Federico Sheppard (Wisconsin) who provided information concerning Sturgeon-bladder glues. Thanks also to José Romanillos (Spain) who kindly provided information on Torres’ labels not published in any of his books. Additionally, I wish to extend in advance my thanks to Julia Schultz, research fellow at the Department of Scientific Research of the Metropolitan Museum of Art in New York City, who volunteered to analyze the glue proteins of the original Torres glue to determine the precise type, in addition to providing a copy of her research on protein glues and their identification. I particularly wish to thank Arian Sheets, curator of string instruments at the National Music Museum of Vermillion, South Dakota, for her encouragement to retain as much original material as possible, and Jason Dobney, Associate curator of musical instruments at the Metropolitan Museum of Art in New York, who introduced me to Julia Schultz. They have all contributed immensely to the success of this restoration and I thank them all.

Richard Bruné began making guitars in 1966 and is a former professional flamenco guitarist. He has written for the Guild of American Luthiers and other organizations and lectured at guitar festivals and museums including the Metropolitan Museum of Art in New York City. He collects classical and flamenco guitars. He was recently featured on the PBS documentary, “Los Romeros: The Royal Family of the Guitar,” and his new book, The Guitar of Andrés Segovia: Hermann Hauser 1937, was recently published by Dynamic, of Italy. You can write to him at 800 Greenwood Street, Evanston IL 60201, or visit rebrune.com.

This article originally appeared in VG‘s May 2008 issue. All copyrights are by the author and Vintage Guitar magazine. Unauthorized replication or use is strictly prohibited.